How Komet® Carbide Burs Are Made

Crafting Tungsten Carbide Burs: A Step-By-Step Journey

Previously published on the Komet USA blog.

The Journey to Quality Begins

1. Cutting Steel

The journey begins with precision. A machine carefully cuts the steel to the required length, giving it the distinctive beveled tip that defines the starting point of your dental tool.

2. Tempering

The steel portion destined to become the neck of the instrument undergoes a rigorous process of heating and cooling, enhancing the carbide's toughness and resilience.

3. Soldering

In a delicate operation, the tungsten carbide is expertly soldered onto the elongated steel piece, which was meticulously crafted in the first step.

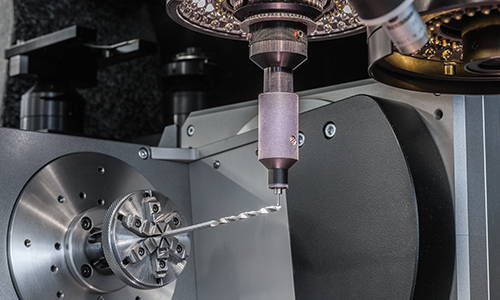

4. Form Grinding

This is where the magic happens. The working part of the bur takes shape, while the neck is expertly ground to ensure optimum performance.

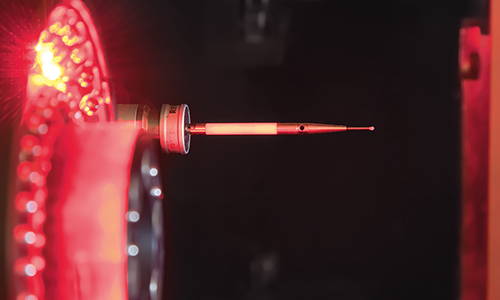

5. Flexural Strength Test

To guarantee exceptional durability, a critical strength test is conducted, applying loads at three points to assess the integrity of the two-piece construction.

6. Toothing

The blank carbide burs are meticulously ground to their specific toothing patterns, including staggered, crosscut, and more. Did you know that Komet's Q-Finishers™ boast a unique cross-cut toothing? This special feature ensures unrivaled accuracy, efficiency, and patient comfort.

7. Shank Grinding

8. Optional Shank Coating

In some cases, Komet's carbide burs are bathed in a specialized coating to change the color of the shank, tailored to specific requirements.

9. Colour Coding

Dental precision is paramount. Each carbide bur is colour-coded according to the number of blades, simplifying selection and ensuring the right tool for the job. For an in-depth understanding of Komet carbide colour-coding system, check out our informative guide.

10. Quality Check

Quality is Komet's commitment. Every production batch undergoes a rigorous inspection process, ensuring each bur meets the highest standards, free of imperfections, with accurate colour codes and precise measurements.

10. Packaging

The final stage is as crucial as the first. Komet carbide burs are meticulously packaged under sterile, cleanroom conditions, preparing them for immediate use in your dental practice.

By revealing the craftsmanship and precision that goes into every carbide bur, Komet ensures that your dental tools meet the highest standards of quality and performance. Your patient's comfort and your practice's efficiency depend on these meticulously crafted instruments, and Komet's dedication to perfection shows in every detail.