How to Choose Dental Burs: An Ultimate Guide

Classification of Dental Burs

Do you feel confused trying to choose between the endless choices of dental burs shapes, sizes, and colours?

You know that all dental burs can be grouped and classified by:

Read below to learn more about different numeration systems, ISO standards, and find helpful charts and tips on how to choose the perfect bur for your practice.

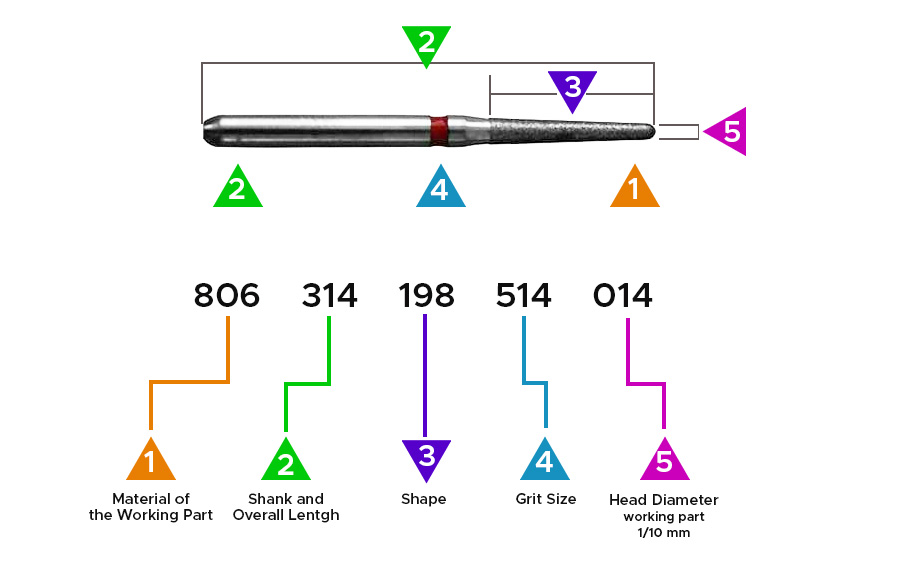

There are two main ways to choose the right dental bur: either by imagining the shape you need and looking for something similar in a catalogue, or by finding and comparing ISO numbers. The ISO system for dental burs is classified by colour and number, which can help simplify the process of choosing the right bur. The classification system indicates the material the bur is made of, the style of the shank, the shape, coarseness, and diameter. Many manufacturers use colours and acronyms to help ease the confusion. Usually, you can find the ISO or a shape designation on the packaging.

Dental Burs Classification:

1. Material – Diamond (806, 807), Carbide (500), Ceramic (005) and Steel (330).

While cutting tools can be made of a variety of materials, the most popular in dentistry is a stainless-steel shank with a diamond coated working end. These diamond dental burs are fabricated by adhering diamond particles to the steel shank using galvanic bonding. Metal, dissolved in an electrolytic bath, is deposited on the steel shank, and entraps the diamond grits until 2/3rds of the particles are covered.

In clinical practice, the exposed diamond chips abrade the tooth structure until the desired shape of the preparation is achieved. The abraded surface of a tooth or composite material has a rough, ‘sanded’ appearance with lots of microscopic dust we commonly refer to as a smear layer.

A carbide dental bur is manufactured from a chunk of tungsten carbide welded to the end of a stainless-steel shank and is then CNC machined to the desired shape and blade configuration. This 2-part construction, when done right, provides the best combination of strength and durability. The tougher carbide working end is designed for multiple uses and resists wear and tear. The carbide flutes, those spiral blades, cleave off the material as it rotates, leaving a relatively smooth surface much like a woodworking plane rather than sandpaper, and is generally easier to subsequently achieve a high shine polish. Read Komet USA blog post with the detailed description of the carbide manufacturing process.

Some burs are made of ultra durable ceramic material for either caries removal or implant sites or denture adjusting. Fabrication of ceramic tools is far more costly, but the durability factor is substantially increased and justifies the increased price.

Steel burs were introduced along with the first rotary dental drill almost 300 years ago and are still used in limited applications today. The softer metal and the rust factor make steel burs impractical for use in modern dentistry save for a few procedures mainly involving amalgam restorations.

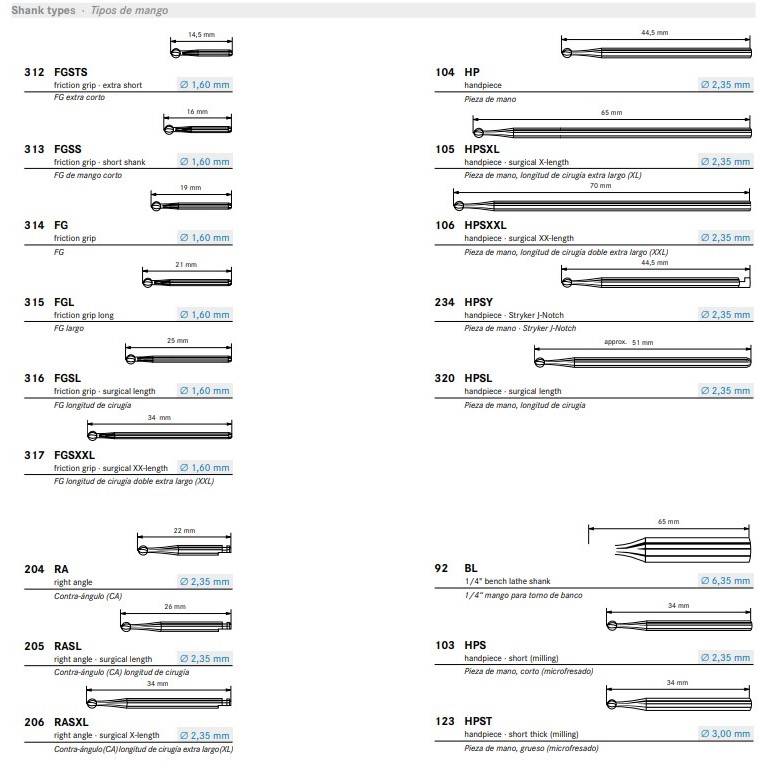

2. Shank and overall length

Three main types of handpieces are used in a dental office and all three have different shank requirements:

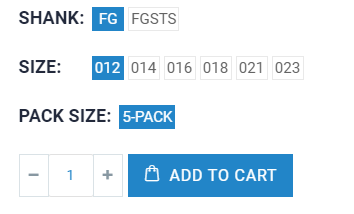

1. High Speed handpieces use a tiny 1.6 mm diameter shank, and the spinning of bur helps keep it securely retained in the head of the handpiece. The operational bur speed of a dental air-driven or electric motor is 200,000 rpm and the chucking mechanism employs the rotational forces to increase the retentive grip on the bur. FG burs fit in a High Speed air handpiece or a red dot (FG) attachment. These friction grip (FG) shanks come in a variety of lengths from Shorter than Short (STS) to surgical length (SL) depending on the application.

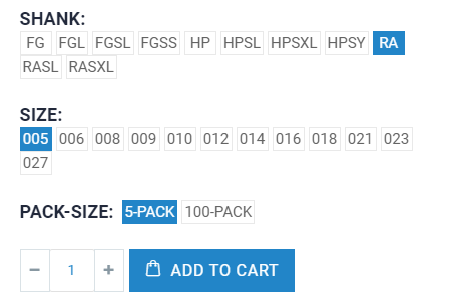

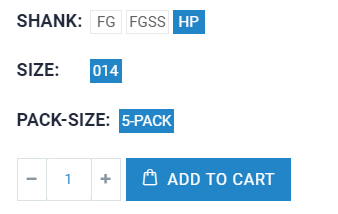

Information about the Shank Type is found on every Komet product page:

2. Right Angle Latch or Slow Speed handpieces rely on a retentive notch at the base of the shank to secure the bur in the handpiece using a flip latch or push-button mechanism. The max speed of a slow speed air handpiece is generally less than 25,000 rpm.

RA (latch) burs fit in a Slow Speed air attachment or the Blue ring (RA) attachment.

3. There are two versions of a Straight Slow Speed handpiece: the air variety commonly found on the rack of a dental delivery unit and the electric motor used in a ‘lab’ setting. Both are used for adjusting appliances extra-orally in a dental office and both use the longer HP shank burs. Longer HP shank burs are available for oral surgical procedures and orthopedic surgeries. The more common 44.5 mm length burs are prevalent for lab cutters or acrylic adjusting burs.

The Full Range of the Komet Bur Shanks

Click to open the enlarged image in a new window

3. Shape

Although the ISO shape designation is indicated on most bur packaging, clinicians default to the verbal description or application – a “tapered round end” for C&B rather than “shape 198”. The shape and ISO numbering system seems arbitrary and confusing to most end users but is a great way of comparing burs from different manufacturers for acquiring the same bur regardless of the somewhat arbitrary manufacturing number systems.

ISO vs. Shape

Using the chart below, you can identify a shape number or ISO number for the burs being matched. Comparing one brand to another would be much easier if the manufacturers used the standardized ISO system, all 5 of the ISO parameters would match between manufacturers. Unfortunately, many companies use the shape code identifier which very rarely aligns between competing bur rivals. Bur companies can entice repeated business by calling a particular bur by its unique manufacturer shape code or name, as that bur becomes familiar to the purchaser.

These unique numbering codes are marketing tactics, method of retaining as much repeated business as possible since many end users are confused by the lengthy manufacturing order codes. Reordering familiar favourites usually involves the path of least resistance - save the package from the last order, re-order that code. When searching for a new solution like an effective Zirconium cutting diamond or a bur to remove a non-precious metal PFM involves a detailed conversation with a bur ‘specialist’ that can act as a sommelier of sorts to assist with the selection, procurement and organization of the burs needed to perform the variety of procedures patients require.

Bur specialists will have the resources available to decipher these codes and implement a re-order and storage system to ensure the proper assortment of burs. Enlisting the services of technical sales reps that understands burs and their functions can greatly ease the confusion and frustration of acquiring the ‘right’ burs for your practice.

ISO / Bur Shape Chart

Description

Image

Shape

ISO Number

End Cutting

839, 840

150

Flame

390, 860, 861, 862, 863

247, 248, 249, 250, 254, 297, 298

Gross Reduction (wavey)

651, 652, 654, 655

511, 512, 513

Knife Edge

825

304

Pointed Cylinder

879, 884, 885, 886

129, 130, 131

Round (+ neck)

802

002

Surgical Length Round

801L

001 (316)

Wheel

818

041, 042

Separation

889

169, 540

Tree

852

161

Note: Clinical Research Dental has more Komet burs in stock than are represented on the website. Contact us at customerservice@clinicalresearchdental.com or Request a demo to find the exact bur you are looking for.

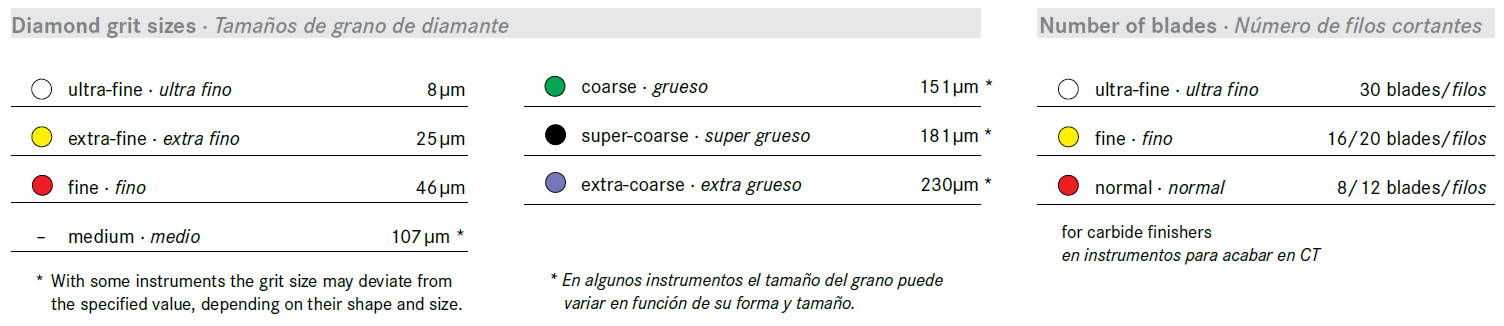

4. Grit Size - Colours

Every diamond bur has a colour ring designating the coarseness and are standardized in the industry by ISO as to the range of diamond particle size. Diamond grits for dental burs are measured in microns (.001mm) as opposed to sandpaper that uses the mesh system – a diamond particle that would pass through a #500 mesh (screen) is 30 microns or less, for example. For those grades where there is a range it is up to the manufacturer to decide exactly the coarseness of their version of the medium, coarse, or super coarse bur – a Komet green stripe, coarse bur is 151µ compared to a BrasselerUSA* black stripe, super coarse that uses 151µ. Read more about Diamond Burs' Colours.

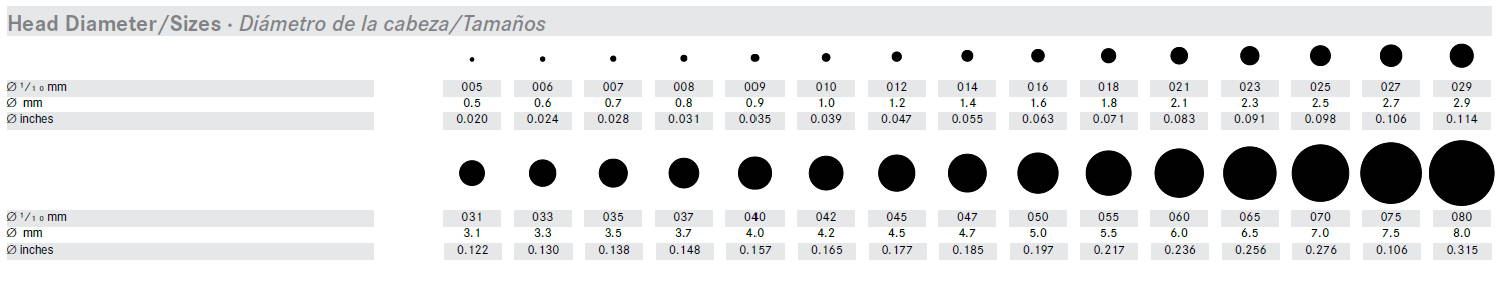

5. Head Size

The last digits of the ISO identifier are the simplest: the indicate the diameter of the cutting head of the bur at the widest point. This dimension is listed in tenths of a millimeter so a cutting head that is the same dimension as the shank for instance will be represented by 016 or 1.6 mm.

This explanation of the dental bur numbering systems might make burs easier to acquire and re-order. However, if you are still confused or don’t have time to match all those numbers, we are here to help:

Request personalized Bur Audit. Change your current burs to the Komet® equivalent and get better results and simplify the reordering process.

Download & print the Komet Bur Conversion card to match your current burs with the Komet ones:

Clinical Research Dental represents the Komet® brand of diamonds and carbides burs in Canada. Founded by the Brasseler family in Germany, the business manufactures the high quality dental diamond, carbide, and ceramic burs and polishing discs and will be celebrating their 100th anniversary in 2023.

Gebr. Brasseler* manufactures internationally recognized instruments for the dental industry under the brand name Komet® and has been supplying the North American dental market directly since 2007. Precise, high-quality instruments of the highest standards. Gebr. Brasseler is the world's largest manufacturer of rotating dental instruments and systems for dentists, dental technicians, oral surgeons, and orthodontists.

*Not to be confused with Brasseler USA which shares the same name, but not the manufacturing facility and standards.

To truly make bur selection easier, request a demo with your local CRD representative to help guide you through the process. We will visit your practice with a bur wallet with physical samples of the burs and create a customized bur ‘menu’ for your office. Additionally, use our handy Bur Conversion Card and send us a close-up photo of a sample bur.

Komet® Bestsellers

Komet Dental offers one of the most comprehensive ranges of rotary dental instruments and systems in the world, including traditional round burs to crown cutters, from composite removers to polishers, from preparation to endodontics. With very few exceptions, Komet Dental manufactures each of its products at the company’s production site in Lemgo, Germany, the home of the family-run company employing more than 1,000 staff. This is where dental quality – made in Germany, yet appreciated all over the world – is created. Explore the Komet Burs collection at CRD or start with these Komet bestsellers.

There's good. There's better. Then there's Komet.